What Is a PTFE Coating?

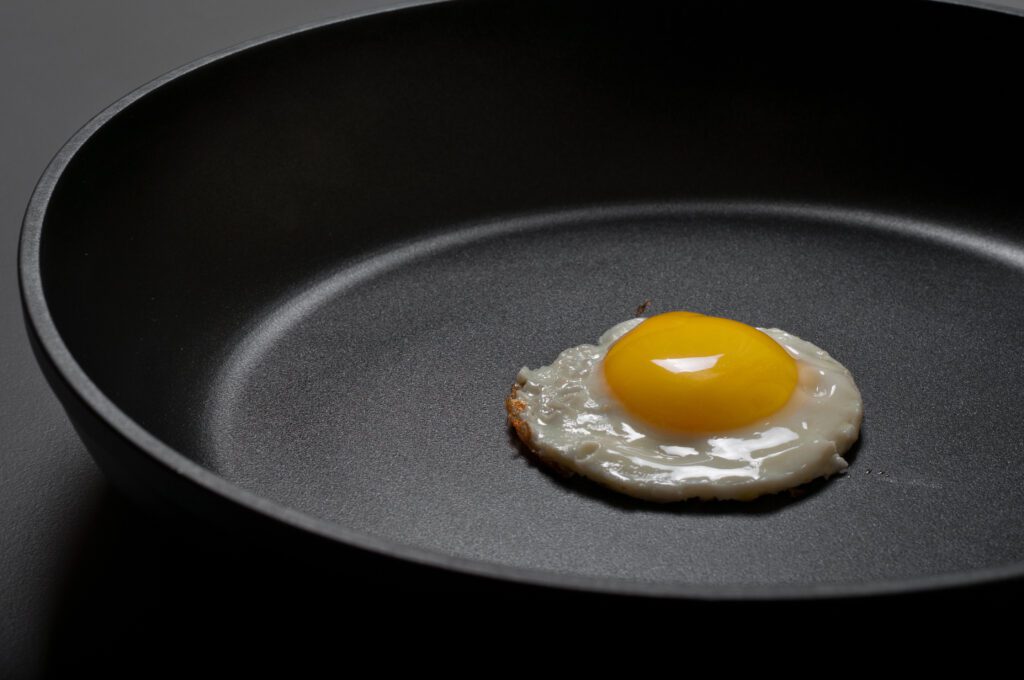

You know your tools and equipment must be maintained for your business’ success. A PTFE coating is a protective coating that will provide your equipment with a slick surface, protection from corrosion, and a longer lifetime. A coating from an experienced application company like us could dramatically reduce your maintenance and replacement costs.

At Precision Coating Technology & Manufacturing, Inc. (PCTM), we have provided cost-effective powder coating solutions for over 30 years. We take pride in delivering solutions to your complex production challenges that increase efficiency, save time, and improve profitability.

One way we do that is with Xylan or PTFE coatings. The generic term for applying these coats is “fluoropolymer coating application.” It’s important to note that the Teflon® brand, another PTFE coating, is a trademarked name despite being commonly used as a generic phrase.

Fluoropolymer coatings can be applied as a liquid spray or as a powder coating. Dry film lubricant coatings typically consist of graphite, molybdenum disulfide, inorganic aluminum silicate, and ceramic-metallic compounds. These coatings are usually applied as liquids and can be sprayed or brushed on as a PTFE paint.

Have a coating project in the works? PCTM is here to help you determine the best industrial coatings for your needs.