Guide to Heat-Resistant Powder Coatings: Which One is Right for You?

Are you tired of your equipment rapidly rusting or corroding due to extreme temperatures and environmental factors? Are your clients demanding longer-lasting equipment and more efficient products? High-heat-resistant powder coatings can provide you with an unmatched degree of strength and durability, particularly when applied by an expert team that understands your specific needs. But do you know how to find the right match for your situation?

It’s time to call Precision Coating Technology & Manufacturing! Extreme temperatures can cause weaker coatings to melt off, and even prolonged exposure to moderately high temperatures can lead to premature aging in metal parts. Protect your employees from equipment failures and extend the lifespan of your equipment with the powder coatings we can provide – call today to find your perfect match!

What Kinds of Heat-Resistant Powder Coatings Are There?

Powder coatings are available in various formulations, each tailored to its intended use. Heat-resistant powder coatings are typically made with chemically reactive resins, which are baked on and take on more heat-resistant qualities after the curing process.

Polyester

While you may be most familiar with polyester as a fabric, this manufactured material also makes an excellent base for corrosion-resistant powder coating. A polyester powder coating can be one of the strongest choices for outdoor equipment thanks to its strong resistance to ultraviolet light, which can degrade other coatings over time.

Epoxy

The standard heat-resistant powder coating epoxy coatings strongly resist abrasion and impact. When your equipment will experience a high degree of commotion, such as during the workday at an industrial or petrochemical plant, you want to choose this powder coating.

Fluoropolymers

Fluoropolymers, such as PTFE, are capable of withstanding extreme heat while providing a near-frictionless surface. These powder coatings are most commonly used in cooking equipment because they are typically food-safe and are essential for non-stick frying pans.

When Do You Need Heat-Resistant Powder Coatings?

If your equipment is exposed to high temperatures, you will notice the difference these compounds can make. But ‘high temperature’ is relative, and some situations that you might not expect could demand extra heat resistance from your equipment. Some of the most common uses of heat-resistant powder coatings include:

Agricultural Equipment

Under the hot sun during the summer heat, metal equipment like tractors can face temperatures in excess of 100 degrees, hot enough to damage powder coatings that aren’t intended for higher temperatures.

Architecture

Much like agriculture, buildings need to be built to withstand high heat. Architectural powder coatings are used to enhance the appearance and durability of items such as windows, doors, and other metal finishes.

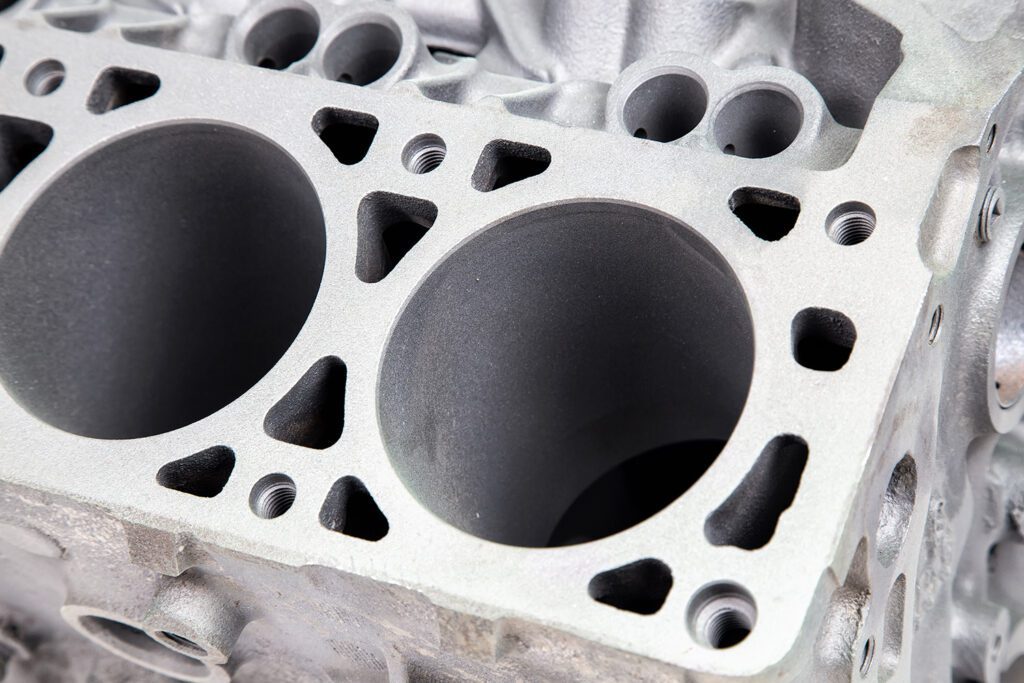

Automotive Industry

Vehicle engine parts can be protected from the harsh environment under the hood by applying a protective layer of powder coating. These coatings can also be used on other parts, such as the exhaust system.

Aerospace Industry

The aerospace industry demands high performance from all parts involved, from jet engines to electrical boxes. Every piece can better withstand the heat generated during flight or on the tarmac with a layer of powder coat.

Industrial

Industrial businesses encompass a vast array of processes, often involving high temperatures. Regardless of the type of metal equipment used, a powder coating layer will enhance durability, corrosion resistance, and heat resistance.

Consider your business carefully when you choose a powder coating. Working closely with your powder coating technicians and service agents can help ensure that your powder coating meets the traits and benefits you need.

Maintenance and Durability

Once you have the powder coating you need, you may worry about how to ensure a long-lasting layer of protection. Powder coatings are designed to reduce maintenance costs and promote a longer-lasting piece of equipment, resulting in minimal work after application. However, discussing post-application maintenance with your powder coating service technician is essential.

Proper maintenance and care of heat-resistant powder coatings include recoating areas with cracks and other touch-up work by professionals, but this shouldn’t be necessary more than once a year. Beyond this, dirt and inappropriate chemical cleaners are the biggest threats to your coatings. Therefore, it is recommended that you carefully clean your equipment with suitable cleaning products, such as a mild soap and a soft brush or towel.

Withstand the Heat with Heat-Resistant Powder Coating

Put expensive replacements and high maintenance costs behind you with heat-resistant powder coatings tailored to your needs. Nothing is more frustrating than tools and parts falling apart simply because you are using them regularly. You can make the most of your equipment with the services of Precision Coating Technology & Manufacturing!

If you call our team today, you will get the service you need to enhance your business, experience more productive workdays, and save money through long-lasting equipment. Call today to get started!