Electrostatic Spray Coating Solutions Customized to Your Needs

Need a beautiful finish that covers every nook and cranny of your tools? Want a protective coating that provides more performance than just color? Electrostatic spray coatings give you a consistent, durable finish that’s perfect for industrial applications. Industries that enjoy the full breadth of benefits include agricultural, automotive, medical, and more. Compared to traditional paints, electrostatic powder coating allows for thicker, tougher, and more even coatings without worrying about running, dripping, or volatile organic compounds (VOCs).

How Electrostatic Spray Coating Keeps You Covered

Electrostatic spray coatings use an electrostatic charge to make colored powder stick to a metal substrate, which is then baked on to create a hard finish. This even coating has an attractive finish that can be produced in a broad spectrum of colors.

An electrostatic spray gun applies a positive charge to the powder material. The metal surfaces being sprayed are grounded, so they are negatively charged. When the powdered particles are sprayed, the electric field creates a strong bond that causes the powder to “seek out” exposed metal and then stick to it in a thick, even coat. This process takes advantage of electromagnetic – or electrostatic – physics. Once sprayed, the powder material is cured with heat, creating a beautiful finish that is durable and chip-resistant.

To find out more about nylon or vinyl coatings for your application, contact Precision Coatings today!

The Benefits and Advantages of an Electrostatic Powder Coating

The primary benefits of an electrostatic powder coating service are the fast production time, the high-quality coating, and the low VOC emissions.

Fast Production

Unlike other coating production processes, electrostatic coatings don’t require extended curing with toxic chemical byproducts. The electrostatic powder coating process uses simple physics concepts to quickly apply even coatings of plastic and polymer powders, which can then be baked onto the item for a long-lasting, smooth, and aesthetically pleasing coating.

Quality Coatings

The strong, even coating produced by an electrostatic powder coating process can last for years to come. These coating types include: epoxies, polyesters, fluoropolymers and urethanes.

These powders offer unique benefits to the end results, from corrosion resistance to a pleasant appearance. Ask us about what would best fit your needs!

Low VOC Levels

Volatile organic compounds are toxic gases that are commonly released by paints, varnishes, and other finishing products. These gases can have highly harmful long-term effects on people exposed to them. These compounds are heavily regulated for work and consumer safety, so the lower levels generated by electrostatic powder coatings are a benefit to the health and safety of both our workers and you!

Electrostatic powder coatings are a leading choice among industry leaders thanks to the unique benefits they can give to your tools and pieces. The electrostatic process is simple enough to be highly flexible for many types of coating. From weather resistance to chemical stability, you can have coatings that will fit your needs exactly. Call us today, and we will start the discussion of what your needs are and how PCTM can meet them!

Conveyor & Batch-Style Electrostatic Spray Coating: Versatility for Any Job Size

Here at PCTM, we offer powder coating solutions for commercial powder coating jobs of any size. Our state-of-the-art facility offers both a conveyor line and batch booth style coating to offer you the best powder coating service according to your specific needs.

Conveyor Electrostatic Powder Coating

In a conveyor system, each part moves smoothly through the powder coating process with no wait or downtime in between steps. Our integrated powder coating line allows us to keep your parts moving seamlessly from beginning to end without any extra handling. Your parts are produced faster and with less labor than batch processing, meaning lower costs for you and more pieces out the door for us.

We leverage our conveyor electrostatic powder coating services for:

- Large-volume orders with rapid throughput

- Smaller parts with similar sizes and shapes

- Parts that don’t require special curing or manual processing

- Spot-checking and correcting any coating issues with minimal waste

This process allows us to scale our production for some of the most challenging jobs. Call today if you need a larger batch of work that aligns with what we describe here!

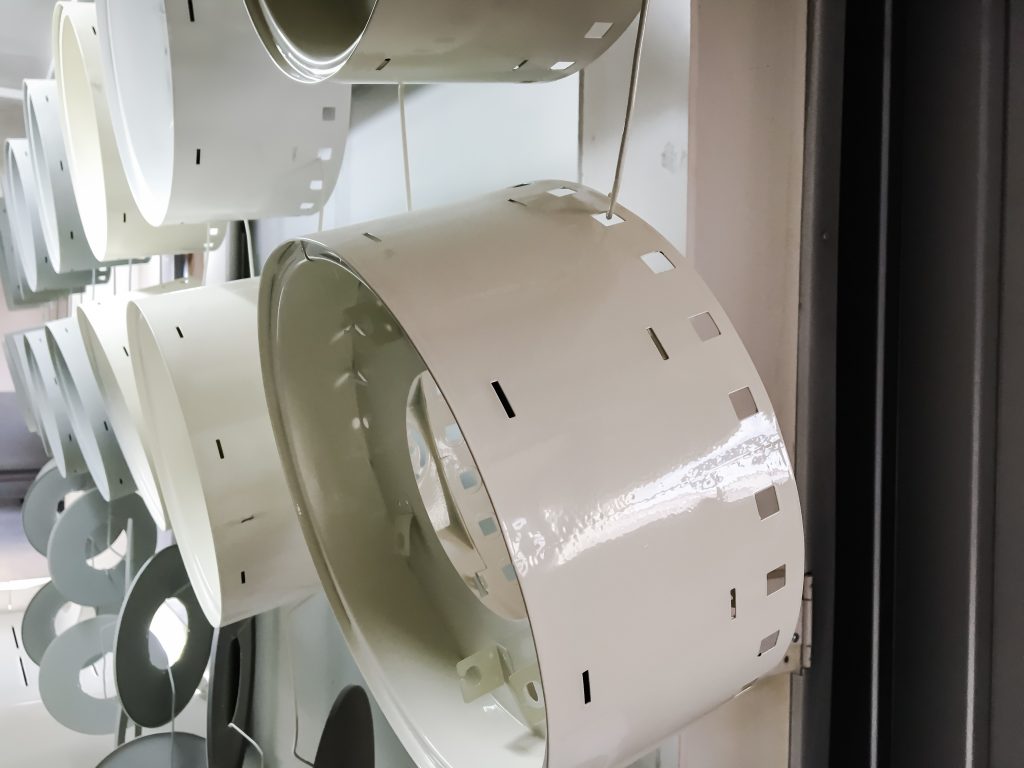

Batch-Style Electrostatic Spray Coating

What if the parts for your job do not meet the requirements of a conveyor line in terms of material selection or part configuration? If you need a more careful and detailed approach to your coating service, then a batch-style electrostatic powder coating system might be the right choice.

The biggest advantage of batch-style powder coating is versatility. While conveyor systems are typically faster, they also need items to be more uniform. A batch powder coating process gives you much more flexibility regarding material selection and part geometry. Batch-style electrostatic spray coating services can be used with conventional thermoset materials such as polyesters, hybrids, acrylics, and epoxies—as well as with more niche thermoplastic materials like nylon, vinyl, and thermoplastic polyesters.

The most common applications for batch-style electrostatic powder coatings include: :

- Small lot sizes not suitable for conveyor line scheduling

- Parts that require masking or are too complex to run through a conveyor line

- Tubular frames with cavities/crevasses that do not drain

- Parts that are too large to fit through the conveyor line (electrical boxes, automotive paneling, etc.)

- Parts that require non-traditional coating materials, such as nylon or vinyl, include items such as truck racks, medical trays, bus panels, and rail transit handrails.

Depending on the thickness desired and the specific application, we can apply nylon coatings with our batch powder coating systems or by using our fluid bed dipping process. Nylon powder coating is highly resistant to corrosion, heat, abrasion, impact, and more. It can stand up to almost anything.

We can also apply vinyl powder coating as a lower-cost alternative to nylon. While not quite as hard as nylon, vinyl coatings still offer excellent weather, impact, and chemical resistance.

Come to Us for High-Quality Electrostatic Coating Services!

If you’ve struggled with equipment and parts breaking down, you know how painful it is to pay for repeat repairs or replacements. With a high-quality coating from PCTM, you can enjoy the benefits of a lower-cost production that can make the most of its tools and equipment. A good powder coating can provide heat resistance, corrosion resistance, and general protection from wear and tear!

Our team knows how necessary your equipment is for your work, and we want to help you get more mileage from your process. Our electrostatic coatings, from urethane to polymers, can meet your specific industry needs. Talk to us today to get started toward high-efficiency production!