The Top 5 Applications and Advantages of PTFE Coatings

Product designers and manufacturers seeking coating solutions that are exceptionally temperature, chemical, and friction-resistant have discovered fluoropolymer coating to be ideal. While the name of this impressive coating may sound foreign, know that it goes by several other common names like PTFE, which stands for Polytetrafluoroethylene – (you can see why it’s abbreviated)! This material has a long history in everyday American life primarily as a cookware coating.

To understand all of the top advantages of PTFE coatings, it is helpful to examine a few of the primary ways they are typically employed. Some are very familiar, like in the pots and pans that you use to prepare meals at home. A wide variety of other unique applications exist, as well, thanks to PTFE’s long list of positive qualities. While PTFE is primarily a metal (steel, alloys, brass, aluminum, etc.) coating, it can be applied to certain plastics and other substances if the surface of that substance is first abraded (made rough in texture) to promote bonding. Whether your priority is food safety, great insulating capability, or general human health, a Fluoropolymer coating could be just what you’ve been searching for to solve your production coating challenges no matter your industry or what you need to coat.

PTFE: A Lucky Breakthrough

First, let’s take a brief look at the history of PTFE, as its distinctly American background has made it a staple in many domestic production processes since its earliest discovery. As with many great scientific innovations, PTFE was first created by accident as the chemist Dr. Roy Plunkett was working in 1938 to produce a new CFC-based refrigerant for DuPont. Plunkett and his associates experienced some setbacks in their intended work, but discovered that their sample of the chemical tetrafluoroethylene had polymerized on its own to create a very slippery substance that proved to be inert to most other chemicals.

Chemours, the arm of DuPont that Plunkett was working for, trademarked PTFE in 1945. It immediately sparked international interest, and the post-WWII manufacturing boom in the US and abroad assured that the technology was soon being experimented with and used in many new applications. In the years ever since, the most enduring uses have been those that solved particularly vexing problems in daily life and also revolutionized society at large.

Medical Instruments

PTFE coatings have many applications in the medical field, from use in the manufacturing of medications (similar to food manufacturing) through protecting delicate surgical equipment. In addition to valuable qualities we’ve already discussed, PTFE is non-reactive to biological fluids. This means that blood and other naturally occurring substances in the human body do not affect PTFE. Surgical instruments and other tools with PTFE coatings can be reused and cleaned time and again without concern for metal contamination in patients.

Technology Applications and Tool Production

One of the most significant applications of PTFE coatings is in the tech sector, including the production of high-tech tools and parts. Up to half of all PTFE coatings are applied to things like wiring and circuit boards that may even travel to space! PTFE has terrific insulative qualities in addition to its high heat resistance, and this places it in high demand as a coating for things like plugs, jacks, and cables that carry electrical current.

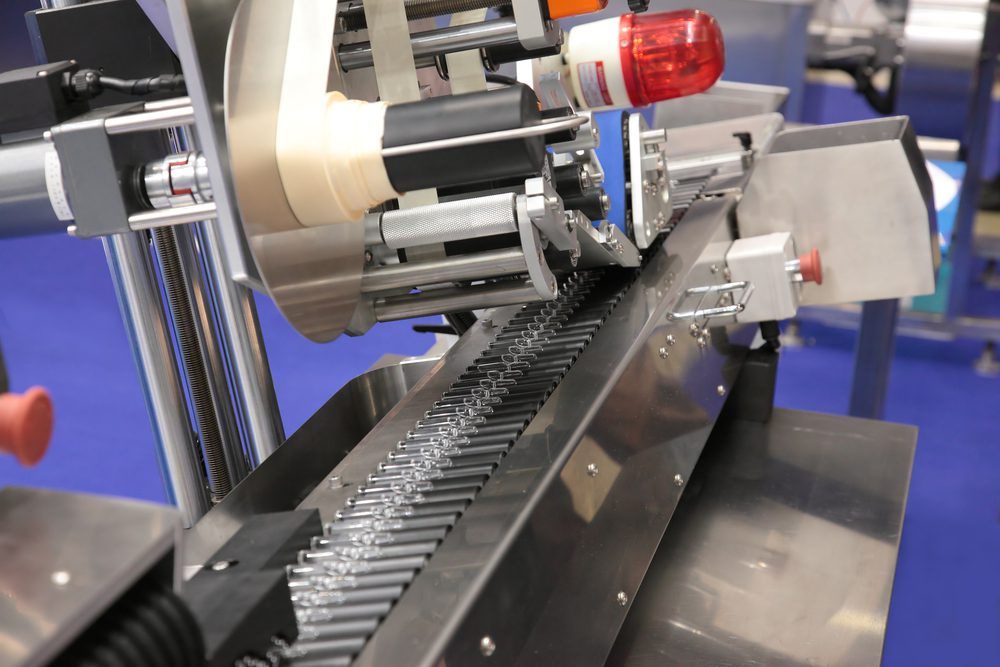

Industrial Uses

As we’ve already discussed, one of the first acknowledged properties of PTFE was its slipperiness. In fact, it remains the most slippery material that exists! This friction-resistant quality makes it highly useful in industrial settings in which gears, bearings, and parts that operate on sliding actions are necessary. PTFE coatings on parts assure that repeated movements don’t cause breakdown or premature wear that could lead to machines seizing up or being rendered inoperable.

Nonstick Cookware

While not necessarily the earliest use of PTFE, the creation of convenient nonstick cookware beginning in the 1950s with French brand Tefal has undoubtedly been the most visible. The first American-made PTFE-coated pan was introduced in the early 1960s, and its name, “The Happy Pan,” tells you everything you need to know about why nonstick cookware took off as an innovation. Today, numerous cookware brands have created proprietary PTFE coatings that claim additional specific benefits beyond the simple nonstick capability.

So why has PTFE remained so popular as a coating for frying pans and soup pots? The advantages that the coating offers that none have matched are high heat-resistance and hydrophobic (water repelling) properties. PTFE coatings do not begin to melt until temperatures reach 620° F — much hotter than can be achieved on the stovetop. And water repellency means that many liquids will not adhere to a pan’s coated surface, which equals much less work in cleanup after a meal. Additionally, because PTFE is so chemically inert, it is safe to use with all types of foods without the risk of contamination.

Food Processing Operations

For reasons similar to why it’s so great for nonstick cookware use, PTFE coatings are used in many different ways in food production facilities. Its chemically inert nature further means that PTFE doesn’t take on flavors or smells from the environment or products that it’s continually in contact with, unlike plastics or other common substances. Food processing machinery, which is either always in contact with food components or being repeatedly sanitized, could indeed not exist without PTFE. Because it’s so safe, even at high temperatures, it’s also compliant with government authorities that oversee food production like the FDA.

Unique and Interesting Applications

While not necessarily always applied as a coating, PTFE as a material has many additional uses. Roofing is one of these that may seem odd at first, but actually makes a lot of sense in many climates and environments. Atlanta’s former Georgia Dome, which hosted the Olympics and a Super Bowl in its 25-year life, featured a PTFE coated fiberglass roof. And there is a style of roofing known as tensile roofs on indoor/outdoor-type venues that utilize PTFE sheets to create a tent-like appearance.

Did you know that insects cannot climb PTFE-coated surfaces? And they are the only known surfaces that geckos can’t stick to with their feet! If you need to keep creepy-crawlies off of a surface, PTFE coating will do the trick. Additional unique applications that you probably haven’t considered include on ski bindings (for the anti-friction capability) and outdoor apparel (for water and stain repellency). When not used as a coating, PTFE is also a helpful substance for things like thread seal plumbing tape, bicycle lubricants, valve oil for brass musical instruments, and many other items you probably use regularly. In a tape format with adhesive backing, for instance, PTFE can even be used to prevent friction-induced blisters on sensitive skin.

Here at Precision Coating Technology & Manufacturing, we offer spray PTFE coatings to suit a wide range of applications. Get in touch with us today to discuss your needs and find out more about our expertise and process.