Blog

Medical-Grade Powder Coating: Biocompatibility Testing for Medical Devices

The medical industry understandably has high expectations for the equipment they use. Strict regulations push medical professionals to choose only the best equipment and only the most effective tools. That’s why more and more OEMs and engineers are turning to powder-coated medical devices. Medical-grade powder coatings are used across the industry to provide doctors and nurses with medical equipment that uses the protective layers of powder coating. This finish does not interfere with patient success and helps provide exceptional care to the patient.

Powder coating is a process that has a wide array of uses and benefits. These coatings are resistant to wear and tear, form a solid layer when applied over the material, and come in a wide array of materials that have unique benefits and applications. We at Precision Coating Technology & Manufacturing (PCTM) are experienced with a full array of such coatings, including medical-grade powder coatings.

This blog post will walk through some of the finer details of powder coatings in the medical industry. And if you are ready to enhance your medical equipment and experience these benefits, request a quote today!

Continue Reading…How Industrial Powder Coating Ovens Provide Flawless Finishes

Are you tired of inconsistent and unreliable results in your finishing process? Do you find yourself constantly dealing with issues like uneven coating thickness or poor adhesion? These issues can lead to scrap parts, wasted time and money, and aggravation. But luckily, it doesn’t have to be that way. Powder coating, which involves melting powder particles onto a metal substrate and then curing in an industrial powder coating oven, can be an economical, time-saving solution.

At Precision Coating Technology & Manufacturing (PCTM), we understand the frustrations that product designers, engineers, and OEMs face when it comes to achieving optimal finishing results. In this blog post, we will delve into the crucial role that industrial ovens play in the powder coating process and how these ovens ensure a uniform curing process, enhance adhesion, and contribute to the overall durability of the finished product. By understanding the importance of proper curing and the benefits of utilizing the right industrial oven, you can maximize production efficiency, manage costs, and prevent expensive product redesigns.

Ready to revolutionize your powder coating process? Contact Precision Coating Technology & Manufacturing today for a quote on your powder coating project. Let us show you the transformative power of our industrial powder coating ovens and how they can elevate your coatings to new levels of excellence. Together, we can achieve consistent, durable, and flawless finishes that exceed your expectations.

Continue Reading…Automotive Powder Coating Provides Enhanced Vehicle Protection and Beauty

Not long ago, coating parts in the automotive industry involved liquids that created waste and harmed the environment. Not only that, but it was also difficult to coat unusual shapes, and these conventional coatings couldn’t stand up to the high heat of the engine compartment. But everything changed when powder coating took over the automotive market.

Automotive powder coating is the cost-effective, solvent-free, and chip-resistant way to give your car parts an attractive appearance for your customers. Plus, we make it easier than ever before to coat thousands to hundreds of millions of parts quickly and efficiently. By using powder coatings, your car parts will receive a high-quality, corrosion-free, and beautiful finish that is highly sought-after in the automotive sector. Best of all? This process produces less waste than other types of liquid coatings.

Don’t wait any longer! Find out the benefits and uses of the environmentally friendly alternative to liquid paint or ceramic coating in this blog post, then get a quote today to get started on your automotive powder coating project!

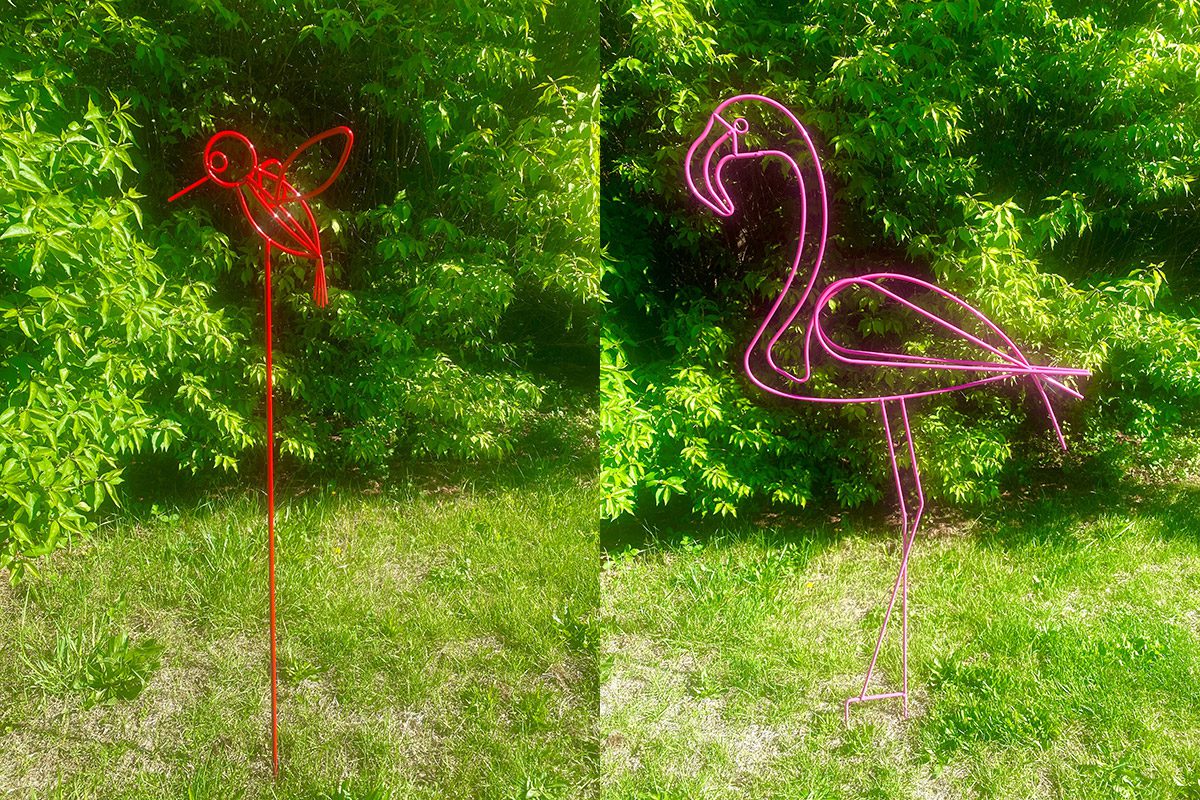

Continue Reading…Amish Metal Works: Fun Powder Coating Ideas

Powder coating is a popular way to add durability and a unique finish to metal items. It is also an eco-friendly and cost-effective option compared to traditional paint. In this article, we will discuss some fun powder coating ideas and the process of powder coating, including the equipment and supplies used, the curing process, and the flow modifiers and additives used to control the desired finish.

Precision Coating Technology & Manufacturing is dedicated to providing our customers with the highest quality powder coating services. Our experienced professionals use state-of-the-art equipment and the latest technologies to ensure all projects are done quickly and accurately. We offer a wide range of colors, textures, and finishes so you can find the perfect look for your project.

Continue Reading…What Happens Inside a Powder Coating Shop?

Have you ever wondered what happens inside a powder coating shop? What is the process involved in creating a perfectly powder-coated surface? And how can powder coating help you to create or enhance the look and function of your equipment, products, or projects? In this blog post, we will explore the process of powder coating, the different types of projects that can be powder coated, and the benefits of using this service for your equipment or project.

Whether you want to become a powder coating professional or aim for better protection against rust for the equipment you manufacture, learning more about this durable coating system can help you feel confident in your choice. Learn more about what happens at our shop and how we can help you.

Continue Reading…6 Advantages of Using Plastisol for Electronics

If you manufacture electronics, you know one of the challenges you have is how to protect the delicate and often small components of your products. As more items become electronic—from the locks on your home to the key to start your car—electronic manufacturers will continue to face these challenges, especially as devices get smaller. Many businesses like yours turn to coatings for these devices, such as metal, plastic, rubber, or composite coatings. Yet, there is one clear winner here: plastic.

Continue Reading…What is Vinyl Dip Coating, and What Items May Benefit from It?

Tool handles, automotive parts, picnic benches, and deep-fryer baskets made from metal have a sturdy structure. That structure is necessary for all of these tools to manage the demands of jobs across industries. However, the environments in which we use these parts can wear down the metal, leading to a structural decomposition over time. Even the acids on the human hand can erode metal tools, and any metal object exposed to the elements will almost certainly develop rust.

That’s why product designers and OEMs turn to vinyl dip coating to protect metal objects. Precision Coating Technology and Manufacturing (PCTM) uses plastisol powder for our vinyl dip coatings, providing a strong, even finish that can be customized to a unique color. This type of powder coating provides a soft yet durable outer layer that protects against corrosion, oxidation, and abrasion.

Learn more in today’s blog post about vinyl coating and how it can benefit your project. Then, contact our team for a quote on your next vinyl plastisol dip-coating project!

Continue Reading…5 Stages of Powder Coating: Why Each Step is Necessary for a Durable Finish

Many product designers, OEMs, and manufacturers like you choose metal for their products. Its versatility, durability, sustainability, and cost-effectiveness make it an attractive material to make various products—from housewares and outdoor furniture to machinery and automotive parts. Yet, one of its downfalls is it’s susceptible to corrosion, oxidation, and wear.

That’s why so many companies turn to powder coating for their metal products and machinery. Powder coating has been around for over 75 years and continues to be a superior coating that makes metal parts more robust, more durable, corrosion-resistant, and wear-resistant. The five stages of powder coating are cheaper to apply, last longer than paint, and are available in a wide variety of colors to customize your part.

To get that protective coating your steel and aluminum parts need, choose Precision Coating Technology & Manufacturing! We’ve been a leader in the powder coating industry for over 30 years and have the equipment, knowledge, and superior service to ensure we’ve done your part coating correctly. We enjoy taking on complex and unique jobs that others won’t touch and providing excellent work for our customers. Get started by learning about our coating process and request a quote today!

Continue Reading…What Coating Offers the Best Marine Corrosion Protection for New Steel?

There is no doubt that steel is a superior product for marine applications. It’s relatively low cost, extremely strong, and an easy substrate to fabricate into specific designs. Yet, its drawback is that when exposed to the harsh conditions of saltwater, the material begins to rust, jeopardizing the integrity of the ship or other marine apparatus.

That’s why manufacturers who make steel products for the water need appropriate marine corrosion protection to keep the inherent durability properties of the substrate intact. Four popular anti-corrosion options include cathodic protection, painting the surface, galvanizing the steel, and powder coating the product. Each comes with advantages, but there is one clear winner: fluid bed powder coating.

Here at Precision Coating Technology & Manufacturing, we have been helping product designers and manufacturers for over 30 years get the powder coating protection they need to create long-lasting, durable products that are resistant to corrosion, abrasion, and wear. Learn more about why powder coating is the best option and how we can help protect your ships, boats, brigades, pontoons, and other water apparatuses from marine corrosion.

Continue Reading…9 Frequently Asked Questions About Fluoropolymer Coating Spray

Fluoropolymer—what? While the name may sound a bit alien to you, fluoropolymer coating is hugely familiar to product designers and manufacturers in many different industries around the world. Also known as polytetrafluoroethylene—or PTFE—this industrial coating compound is ideal for those seeking coating with exceptional temperature, chemical, and friction-resistant properties.

In today’s article from Precision Coating Technology & Manufacturing, we’ll examine nine frequently asked questions about fluoropolymer coating spray. After you’ve finished reading it, you’ll have a better understanding of this impressive coating material.

Continue Reading…« Previous 1 2 3 Next »